Your cart is currently empty!

China Good quality 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor air compressor oil

China Good Quality 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor

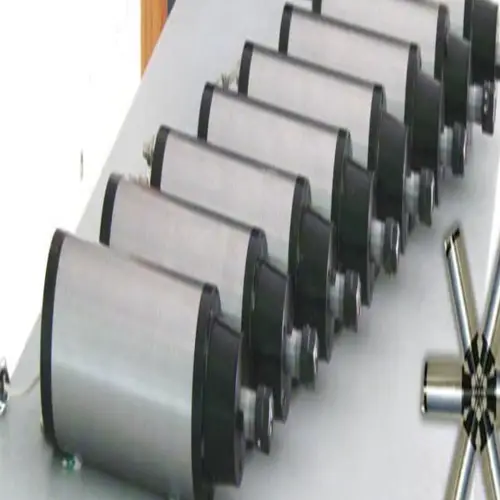

Looking for a high-quality spindle motor that delivers top performance? Look no further than our 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor. This spindle motor is designed to meet your needs for precision and accuracy, making it perfect for milling, drilling, and other cutting applications. With its durable construction and advanced features, this spindle motor is the perfect choice for any industrial or commercial application.

Product Description

Our 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor is a top-performing spindle motor that delivers exceptional precision and accuracy. With a voltage of 220V and a current of 6.5, this spindle motor is designed to deliver high-speed performance that meets your needs for precision cutting, drilling, and milling. It features a maximum speed of 24000 R/min and a power output of 800 W, making it perfect for a wide range of industrial and commercial applications.

Constructed with C grade high-speed angle contact ball bearings, this spindle motor is designed to provide exceptional support and accuracy under high speeds. It also features an advanced cooling system that helps to dissipate heat and keep the spindle motor running smoothly, even during extended use. And with its grease lubrication and ER11 collet chuck, this spindle motor is designed to deliver exceptional performance that meets your needs for precision and accuracy.

Constructure Features

Our 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor is designed with a range of advanced features that set it apart from other spindle motors on the market. Some of the key features of this spindle motor include:

- Constructed with C grade high-speed angle contact ball bearings for exceptional support and accuracy

- Advanced cooling system to dissipate heat and keep the spindle motor running smoothly

- Grease lubrication and ER11 collet chuck for exceptional performance and precision

- Can use greese and greese mist lubrication 2 methods depending on application

- Air-cooled spindle can work for up to 24 hours without the need for human intervention

STEPPER MOTOR IN HOT SELLING

In addition to our 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor, we also offer a range of other high-quality industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to delivering top-quality products at competitive prices, backed by exceptional customer service and support. Customers are welcome to customize their orders with drawings and samples, and we are always here to answer any questions you may have about our products and services.

Frequently Asked Questions

1. What is the maximum speed of the 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor?

The maximum speed of this spindle motor is 24000 R/min, making it ideal for precision cutting, drilling, and milling applications.

2. What type of bearings does this spindle motor use?

This spindle motor uses C grade high-speed angle contact ball bearings for exceptional support and accuracy under high speeds.

3. Can this spindle motor be used for extended periods without the need for human intervention?

Yes, the air-cooled spindle can work for up to 24 hours without the need for human intervention, making it ideal for industrial and commercial applications.

4. What lubrication methods does this spindle motor use?

This spindle motor can use both grease and grease mist lubrication methods depending on the application.

5. What other products does your company offer?

In addition to our 0.8kw Water Cooling Spindle Motor High Speed Spindle Milling Spindle Motor, we offer a range of other industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

Introduction to Spindle Motor Performance Characteristics

Spindle motors are an essential component of modern-day machinery, especially in the CNC machining, robotics, and textile machinery fields. They are known for their high performance and precision in rotating mechanical parts. The following are some of the main performance characteristics of Spindle Motors:

High Speeds and Precision

Spindle motors can achieve high rotational speeds, ranging from a few hundred to tens of thousands of revolutions per minute (RPM). They are also known for their precision, which is essential in many applications, particularly in the field of CNC machining.

High Torque

Spindle motors are capable of producing high torque, which is necessary in applications that require high power output. The torque produced by the spindle motor can be adjusted to suit the requirements of the application.

Low Vibration and Noise

The spindle motor’s design is such that it produces low vibration and noise levels. This is because the motor’s bearings are precisely aligned, reducing the chances of any vibrations or noise being produced during operation.

Types and Characteristics of Spindle Motors

Spindle motors can be classified into various types based on their design, application, and performance. Some of the most common types include Belt-driven Spindle Motors, Direct Drive Spindle Motors, and Air-Bearing Spindle Motors. Each of these types has its unique characteristics, advantages, and disadvantages, depending on the application.

Advantages of Spindle Motors Made of Different Materials

Spindle motors can be made from different materials such as stainless steel, ceramic, and aluminum. Each material has its advantages, such as durability, heat dissipation, and resistance to corrosion. Choosing the right material for the spindle motor is essential in ensuring that the motor performs optimally and lasts longer.

Future Development Trends and Opportunities of Spindle Motor Products

As technology advances, the demand for spindle motors is expected to increase. The future development of spindle motor products will focus on improving the motor’s performance, reducing power consumption, and increasing efficiency. This will create opportunities for manufacturers to develop new products and improve existing products.

How to Choose a Suitable Spindle Motor

Choosing the right spindle motor for your application is critical in ensuring that your machinery operates optimally. Several factors need to be considered when selecting a spindle motor, such as power requirements, speed (RPM), torque, cooling system, type of spindle taper, and control system compatibility. These factors will help determine the type of spindle motor suitable for your application.

Conclusion

Spindle motors are a crucial component of modern machinery. They offer high performance, precision, and reliability, making them essential in various industries. Choosing the right spindle motor is critical in ensuring that your machinery operates optimally, and considering the factors discussed above will help in making the right choice.

Author: Dream

Disclaimer: All the content on this page is from the Internet and is only for product selection reference. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.