Your cart is currently empty!

China Hot selling Hot Sell High Speed Spindle 1.5kw 400Hz 24000rpm Er11 Air Cooled CNC Spindle Motor for CNC Router with Best Sales

China Hot Selling CNC Spindle Motor for CNC Router

Introducing our high-speed spindle motor, designed for CNC routers, with a power of 1.5kw and a frequency of 400Hz. This air-cooled spindle motor is equipped with P4 high-speed angular contact bearings, ensuring high rotation accuracy even at high speeds.

Product Description

Our CNC spindle motor offers several advantages:

1. High Rotation Accuracy

Equipped with high-precision collet nuts and P4 high-speed angular contact bearings, our spindle motor ensures precise rotation even at high speeds.

2. Efficient Heat Dissipation

The air-cooling system provides effective heat dissipation, eliminating the need for water pipes or sinks. Simply connect the motor to the inverter for convenient operation.

3. Enhanced Lubrication

Our spindle motor utilizes high-temperature resistant grease lubricating oil, ensuring smooth and efficient operation even at temperatures up to 200 degrees Celsius.

4. Durability and Stability

Constructed with high-quality stainless steel, our spindle motor offers excellent durability, rust resistance, and stability. It is designed to have a longer lifespan, providing reliable performance for your CNC router.

Specifications

| Model | GDZ80-1.5KW 24Z |

| Gross weight | 5Kg |

| Collet | ER11 |

| Frequency | 400Hz |

| Speed | 24000r |

| Rated power | 1.5KW |

| Voltage | 220V |

| Current | 5A |

| Cooling type | Water cooling |

Applications

Our CNC spindle motor is suitable for high-speed and high-precision milling, drilling, and tapping of various metal and non-metal materials. It can handle materials such as acrylic, PVC, wood, marble, rubber, and glass.

If you have specific engraving requirements or materials, please feel free to consult us for personalized solutions.

Precautions

To ensure optimal performance and longevity of our spindle motor, please follow these precautions:

1. Proper Inverter Usage

Always use our motorized spindle in conjunction with a compatible inverter. Make sure the specifications and parameter settings of the inverter match the rated parameters of the spindle to avoid damage.

2. Clean Tool Clamping

Before clamping the tool on the electric spindle, ensure that the collet, nut, and inner taper hole are clean to maintain accuracy. The tool holder should be inserted into the collet with a diameter greater than 15mm.

3. Preheating and Operation Time

Preheat the electric spindle during daily processing. Once the spindle reaches the desired processing speed, perform machining for 15-20 minutes. It is recommended to allow the spindle to rest for 2 hours daily to restore mechanical fatigue and prolong its service life.

4. Avoid Impact

Avoid knocking the end cover, collet, and cutter head during tool unloading. Additionally, ensure the electric spindle is not subjected to bumps or impacts during transportation, storage, and use, especially at the shaft end.

5. Proper Air Source

Use an air source through an oil-water separator and a dry filter when operating the electric spindle. Maintain an air pressure of 0.2-0.25MPA with a filtration accuracy of 5MM to prevent bearing damage.

About Our Company

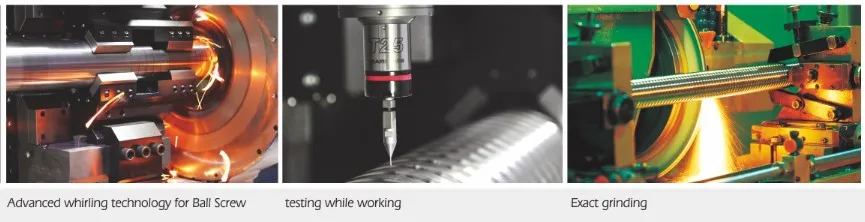

We are a leading provider of industrial products, specializing in agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our goal is to provide high-quality products, competitive prices, and excellent customer service.

Image:

Frequently Asked Questions

Q: Are you a trading company or a manufacturer?

A: We are a motor manufacturer in China with 15 years of experience.

Q: How can I place an order?

A: Simply send us an inquiry, and we will provide you with a quotation. Once the details are negotiated and samples are confirmed, we can proceed with a contract/deposit for mass production. The delivery time usually ranges from 15 to 25 working days.

Q: What if my package is missing products?

A: Please contact our support team, and we will verify the contents of your order. We apologize for any inconvenience caused.

Q: What payment methods do you accept?

A: We accept payment by T/T and PayPal. If you require alternative payment methods, please contact us in advance. A deposit of 30%-50% is accepted, with the balance to be paid before shipment.

Q: How long does delivery take?

A: The delivery time depends on the quantity of your order. Typically, it takes 15-25 working days.

Introduction to Spindle Motor Performance Characteristics

Spindle motors are an essential component of modern-day machinery, especially in the CNC machining, robotics, and textile machinery fields. They are known for their high performance and precision in rotating mechanical parts. The following are some of the main performance characteristics of Spindle Motors:

High Speeds and Precision

Spindle motors can achieve high rotational speeds, ranging from a few hundred to tens of thousands of revolutions per minute (RPM). They are also known for their precision, which is essential in many applications, particularly in the field of CNC machining.

High Torque

Spindle motors are capable of producing high torque, which is necessary in applications that require high power output. The torque produced by the spindle motor can be adjusted to suit the requirements of the application.

Low Vibration and Noise

The spindle motor’s design is such that it produces low vibration and noise levels. This is because the motor’s bearings are precisely aligned, reducing the chances of any vibrations or noise being produced during operation.

Types and Characteristics of Spindle Motors

Spindle motors can be classified into various types based on their design, application, and performance. Some of the most common types include Belt-driven Spindle Motors, Direct Drive Spindle Motors, and Air-Bearing Spindle Motors. Each of these types has its unique characteristics, advantages, and disadvantages, depending on the application.

Advantages of Spindle Motors Made of Different Materials

Spindle motors can be made from different materials such as stainless steel, ceramic, and aluminum. Each material has its advantages, such as durability, heat dissipation, and resistance to corrosion. Choosing the right material for the spindle motor is essential in ensuring that the motor performs optimally and lasts longer.

Future Development Trends and Opportunities of Spindle Motor Products

As technology advances, the demand for spindle motors is expected to increase. The future development of spindle motor products will focus on improving the motor’s performance, reducing power consumption, and increasing efficiency. This will create opportunities for manufacturers to develop new products and improve existing products.

How to Choose a Suitable Spindle Motor

Choosing the right spindle motor for your application is critical in ensuring that your machinery operates optimally. Several factors need to be considered when selecting a spindle motor, such as power requirements, speed (RPM), torque, cooling system, type of spindle taper, and control system compatibility. These factors will help determine the type of spindle motor suitable for your application.

Conclusion

Spindle motors are a crucial component of modern machinery. They offer high performance, precision, and reliability, making them essential in various industries. Choosing the right spindle motor is critical in ensuring that your machinery operates optimally, and considering the factors discussed above will help in making the right choice.

Author: Dream

Disclaimer: All the content on this page is from the Internet and is only for product selection reference. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.