Your cart is currently empty!

China wholesaler CHINAMFG Air Cooling Spindle Series 7.5kw Square Three-Phase Asynchronous AC Spindle Motor for Wood Carving supplier

CHINAMFG Air Cooling Spindle Series 7.5kw Square Three-Phase Asynchronous AC Spindle Motor for Wood Carving

Looking for a reliable supplier of spindle motors for your CNC router machine? Look no further than CHINAMFG, your go-to source for high-quality spindle motors. Our 7.5kw Square Three-Phase Asynchronous AC Spindle Motor for Wood Carving is designed to provide exceptional performance and reliability, with a range of features that make it ideal for milling, engraving, and drilling. With a spindle type of GDZ120*103-7.5 and a speed of 18000rpm, this motor offers plenty of power to get the job done right.

Product Description

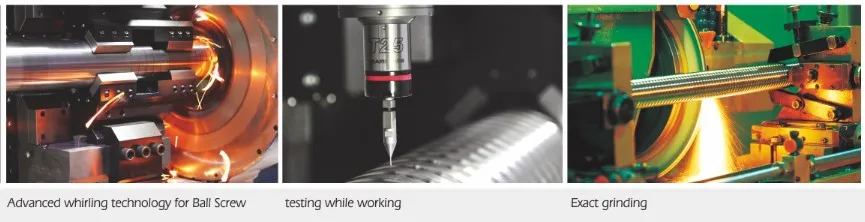

Our spindle motor features high-quality imported bearings that provide a long working life, ensuring you get the most out of your investment. Available in water cooling, air cooling, and self-cooling configurations, you can choose the right one to meet your specific needs. Our motors also undergo a polishing process to improve spindle concentricity, which helps to increase motor working life.

Our spindle motor is available in a range of sizes to meet your needs, including:

- Water cooling: 300w, 800w, 1.2kw, 1.5kw, 2.2kw, 3kw, 4kw, 3.2kw, 4.5kw, 5.5kw

- Air cooling: 800w, 1.5kw, 2.2kw, 3.5kw, 4.5kw, 6kw, 7.5kw, 12kw

- Cooled by self: 400w

- ATC spindle: cooled by water: 1.5kw, 2.2kw, 5.5kw, 6kw, 7.5kw; cooled by air: 8kw, 9kw

- Sealing side spindle: 350w, 550w, 700w, 750w, 1.1kw, 1.8kw, 2.2kw

We also have spindle motor matching inverters (VFD), collets, grippers, and other spare parts available. If you need other kinds of parts, please don’t hesitate to contact us.

Product Parameters

| Spindle type | GDZ120*103-7.5 |

| Square | |

| Speed | 18000rpm |

| Power | 7.5KW |

| Voltage | 220V/380V |

| Current | 20.7A/15.5A |

| Frequency | 300HZ |

| Joint of nose | ER32 |

| Lub | grease |

| Cool | air cooling |

| Bearing type | 7008CP4*2+7004CP4*2 |

| Weight | 18KG |

| Torque | 3.98Nm |

| Collet | ER32 |

| Collet nut | 3.175mm, 6mm, 12.7mm, 20mm |

| Warranty period | Bearings=half a year, other parts a year |

Detailed Photos

Check out our detailed photos to get a closer look at our 7.5kw Square Three-Phase Asynchronous AC Spindle Motor for Wood Carving and see all of its features and benefits.

FAQ

1. What is the warranty period for your products?

Bearings come with a half-year warranty, while other parts are covered for a full year.

2. What kinds of bearings do you use?

The type of bearing we use will depend on your order. We offer different price ranges with different bearings to choose from.

3. Do you have other spare parts for spindle motors, such as grippers, VFDs, and collets?

Yes, we have all of the necessary kits and can even have our engineers help you program them.

4. Is it possible to visit your factory?

Absolutely, we welcome all visitors to our factory.

5. Do you have an installation page?

Yes, we do have an installation page available.

In addition to our 7.5kw Square Three-Phase Asynchronous AC Spindle Motor for Wood Carving, our company supplies a wide range of other industrial products, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products, competitive prices, and outstanding customer service. We also welcome custom orders based on drawings and samples.

Introduction to Spindle Motor Performance Characteristics

Spindle motors are an essential component of modern-day machinery, especially in the CNC machining, robotics, and textile machinery fields. They are known for their high performance and precision in rotating mechanical parts. The following are some of the main performance characteristics of Spindle Motors:

High Speeds and Precision

Spindle motors can achieve high rotational speeds, ranging from a few hundred to tens of thousands of revolutions per minute (RPM). They are also known for their precision, which is essential in many applications, particularly in the field of CNC machining.

High Torque

Spindle motors are capable of producing high torque, which is necessary in applications that require high power output. The torque produced by the spindle motor can be adjusted to suit the requirements of the application.

Low Vibration and Noise

The spindle motor’s design is such that it produces low vibration and noise levels. This is because the motor’s bearings are precisely aligned, reducing the chances of any vibrations or noise being produced during operation.

Types and Characteristics of Spindle Motors

Spindle motors can be classified into various types based on their design, application, and performance. Some of the most common types include Belt-driven Spindle Motors, Direct Drive Spindle Motors, and Air-Bearing Spindle Motors. Each of these types has its unique characteristics, advantages, and disadvantages, depending on the application.

Advantages of Spindle Motors Made of Different Materials

Spindle motors can be made from different materials such as stainless steel, ceramic, and aluminum. Each material has its advantages, such as durability, heat dissipation, and resistance to corrosion. Choosing the right material for the spindle motor is essential in ensuring that the motor performs optimally and lasts longer.

Future Development Trends and Opportunities of Spindle Motor Products

As technology advances, the demand for spindle motors is expected to increase. The future development of spindle motor products will focus on improving the motor’s performance, reducing power consumption, and increasing efficiency. This will create opportunities for manufacturers to develop new products and improve existing products.

How to Choose a Suitable Spindle Motor

Choosing the right spindle motor for your application is critical in ensuring that your machinery operates optimally. Several factors need to be considered when selecting a spindle motor, such as power requirements, speed (RPM), torque, cooling system, type of spindle taper, and control system compatibility. These factors will help determine the type of spindle motor suitable for your application.

Conclusion

Spindle motors are a crucial component of modern machinery. They offer high performance, precision, and reliability, making them essential in various industries. Choosing the right spindle motor is critical in ensuring that your machinery operates optimally, and considering the factors discussed above will help in making the right choice.

Author: Dream

Disclaimer: All the content on this page is from the Internet and is only for product selection reference. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.